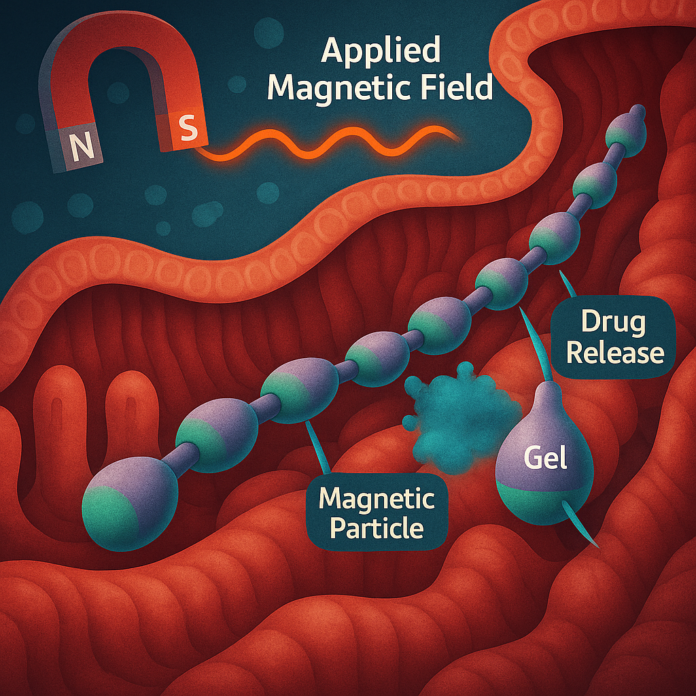

Researchers have developed microrobots capable of navigating through complex biological environments to deliver drugs directly to targeted sites, potentially improving treatment precision and reducing waste compared to traditional intravenous (IV) methods. A study published in Science Advances demonstrated the technology in simulated and experimental models, with applications for conditions such as inflammatory bowel disease and in minimally invasive surgery.

The microrobots, known as permanent magnetic droplet-derived microrobots (PMDMs), are constructed from two-sided particles—one side made of a gel that can carry medication, and the other embedded with magnetic particles for navigation. Each microrobot is roughly 0.2 millimeters wide, about the thickness of two human hairs.

In a test simulating treatment for inflammatory bowel disease, researchers delivered the microrobots into a pig intestine using a catheter. Magnetic fields steered them to specific sites where the gel dissolved, releasing a dye as a stand-in for medicine. The process was designed for both immediate and delayed release, and after delivery, the magnetic components were guided back to the catheter for retrieval. The system could be used to distribute different drugs to multiple inflammation sites in a single procedure.

A separate trial modeled minimally invasive knee surgery. The microrobots were released at an accessible point, guided to a hard-to-reach target, released their cargo, and then navigated back for extraction.

Fabrication uses a microfluidic process in which gel containing magnetic particles flows through a narrow channel, intersecting with a stream of oil that pinches off droplets. Magnetic gel settles to one side, creating the asymmetrical structure needed for control. According to co-lead author Yuanxiong Cao of the University of Oxford, the method can produce hundreds of microrobots in minutes, greatly increasing manufacturing efficiency compared to earlier approaches.

The navigation system uses an electromagnet controlled by commercial software to generate fields that assemble microrobots into chain formations. These chains can “walk,” “crawl,” or “swing” depending on the magnetic field’s frequency, and they can disassemble to pass through narrow openings before reassembling.

Co-lead author Philipp Schönhöfer of the University of Michigan noted the high degree of control possible over assembly and disassembly cycles. The research team is now working on designs to better navigate intricate environments and studying how different particle types and swarm sizes behave under varied magnetic fields.

Parallel advances at the University of Colorado Boulder, published in Nature Communications, detail a new fabrication method for microrobots using two-photon lithography and microstenciling. This allows particles to be shaped and patterned with metal patches as small as 0.2 microns, enabling precise movement in response to magnetic or electric fields. These particles could be used for both biomedical purposes, such as improved drug distribution, and environmental applications, including pollutant removal.

Researchers emphasize that further testing is needed before clinical use, but the results point toward a future in which microrobots could improve targeted therapies, reduce side effects, and broaden treatment options for complex diseases.

This image is the property of The New Dispatch LLC and is not licenseable for external use without explicit written permission.